Ultraviolet (UV) Lithography in Semiconductor Manufacturing: The Game-Changing Technology Powering Next-Gen Microchips. Discover How UV Light Is Shaping the Future of Electronics and Pushing the Limits of Miniaturization.

- Introduction to Ultraviolet (UV) Lithography

- The Science Behind UV Lithography: How It Works

- Types of UV Lithography: Deep UV (DUV) vs. Extreme UV (EUV)

- Key Advantages Over Traditional Lithography Methods

- Challenges and Limitations in UV Lithography

- Impact on Semiconductor Device Scaling and Performance

- Major Industry Players and Recent Innovations

- Future Trends: What’s Next for UV Lithography?

- Conclusion: The Lasting Impact of UV Lithography on Semiconductor Manufacturing

- Sources & References

Introduction to Ultraviolet (UV) Lithography

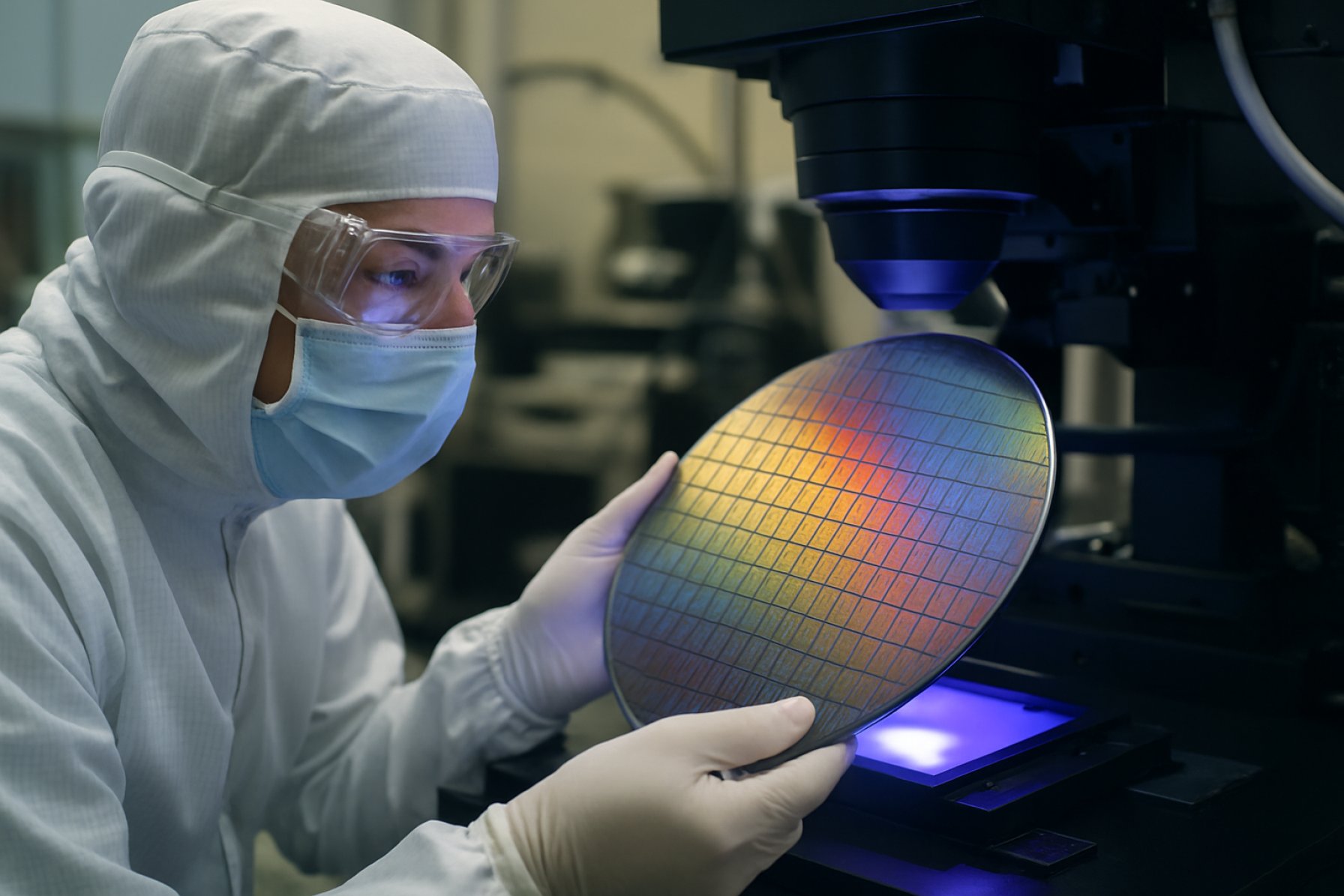

Ultraviolet (UV) lithography is a cornerstone technology in semiconductor manufacturing, enabling the precise patterning of integrated circuits on silicon wafers. This process utilizes ultraviolet light to transfer intricate circuit designs from a photomask onto a photosensitive resist layer, which is subsequently developed to reveal the desired micro- and nanoscale features. The continual drive for smaller, faster, and more energy-efficient electronic devices has pushed the limits of lithographic resolution, making UV lithography an essential technique for producing advanced semiconductor components.

The evolution of UV lithography has been marked by the transition from traditional mercury lamp sources emitting at 365 nm (i-line) to deep ultraviolet (DUV) sources, such as excimer lasers operating at 248 nm (KrF) and 193 nm (ArF). These shorter wavelengths allow for finer feature sizes, supporting the ongoing miniaturization trend described by Moore’s Law. The adoption of advanced photoresists and optical systems has further enhanced the resolution and throughput of UV lithography, making it suitable for high-volume manufacturing of logic and memory chips ASML.

Despite its advantages, UV lithography faces challenges related to diffraction limits, process complexity, and escalating costs as feature sizes shrink below 10 nanometers. These challenges have spurred the development of next-generation techniques, such as extreme ultraviolet (EUV) lithography, which operates at even shorter wavelengths. Nevertheless, UV lithography remains a vital and widely used process in the semiconductor industry, underpinning the fabrication of most modern electronic devices Semiconductor Industry Association.

The Science Behind UV Lithography: How It Works

Ultraviolet (UV) lithography is a cornerstone technique in semiconductor manufacturing, enabling the precise patterning of micro- and nanoscale features on silicon wafers. The process begins with the application of a light-sensitive material called photoresist onto the wafer’s surface. A photomask, which contains the desired circuit patterns, is then aligned over the wafer. When exposed to UV light, the photoresist undergoes chemical changes: in positive resists, the exposed regions become more soluble and are removed during development, while in negative resists, the exposed areas become less soluble and remain after development. This selective removal creates a patterned photoresist layer that serves as a template for subsequent etching or doping steps.

The resolution of UV lithography is fundamentally limited by the wavelength of the light used. Shorter wavelengths allow for finer feature sizes, which is why the industry has progressed from traditional mercury lamps emitting at 365 nm (i-line) to deep ultraviolet (DUV) sources at 248 nm (KrF excimer laser) and 193 nm (ArF excimer laser). The use of advanced optical systems, including high-numerical-aperture lenses and phase-shifting masks, further enhances pattern fidelity and resolution. However, as feature sizes approach the diffraction limit of the exposure wavelength, techniques such as optical proximity correction and multiple patterning are employed to maintain accuracy and yield.

The science behind UV lithography is a delicate interplay of photochemistry, optics, and materials science, driving the continuous miniaturization of semiconductor devices. For a detailed technical overview, see ASML Holding N.V. and Semiconductor Industry Association.

Types of UV Lithography: Deep UV (DUV) vs. Extreme UV (EUV)

Ultraviolet (UV) lithography in semiconductor manufacturing primarily utilizes two advanced types: Deep Ultraviolet (DUV) and Extreme Ultraviolet (EUV) lithography. Both techniques are pivotal for patterning increasingly smaller features on silicon wafers, but they differ significantly in wavelength, technology, and application scope.

DUV lithography employs light with wavelengths typically in the range of 248 nm (KrF excimer laser) and 193 nm (ArF excimer laser). This technology has been the industry standard for several technology nodes, enabling feature sizes down to approximately 7 nm through multiple patterning techniques. DUV systems are mature, widely deployed, and benefit from a robust supply chain and process know-how. However, as device dimensions shrink further, DUV faces physical limitations due to diffraction and the complexity of multi-patterning steps, which increase cost and process variability ASML.

EUV lithography, by contrast, uses a much shorter wavelength of 13.5 nm, allowing for single-exposure patterning of features below 7 nm. This technology dramatically reduces the need for multiple patterning, simplifying process flows and improving yield. However, EUV systems are technologically complex, requiring vacuum environments, specialized reflective optics, and high-power light sources. The adoption of EUV has enabled the production of advanced nodes such as 5 nm and 3 nm, but challenges remain in terms of tool cost, throughput, and mask defectivity TSMC.

In summary, while DUV remains essential for many manufacturing steps, EUV is critical for the most advanced semiconductor devices, marking a significant leap in lithographic capability and industry innovation Intel.

Key Advantages Over Traditional Lithography Methods

Ultraviolet (UV) lithography has emerged as a cornerstone technology in semiconductor manufacturing, offering several key advantages over traditional lithography methods such as contact and proximity printing. One of the most significant benefits is its ability to achieve much finer feature sizes, which is critical for the ongoing miniaturization of integrated circuits. By utilizing shorter wavelengths of light—typically in the deep ultraviolet (DUV) range—UV lithography enables the patterning of features well below one micron, surpassing the resolution limits of older techniques that rely on longer wavelengths or direct contact with the wafer surface ASML.

Another major advantage is the non-contact nature of projection UV lithography, which reduces the risk of mask and wafer contamination and physical damage. This leads to higher yields and improved device reliability. Additionally, UV lithography supports higher throughput due to its compatibility with step-and-repeat or step-and-scan systems, allowing for rapid processing of large wafer volumes Semiconductor Industry Association.

Furthermore, UV lithography is highly adaptable, supporting a range of photoresist materials and process optimizations that can be tailored for specific device requirements. Its scalability has also made it the foundation for advanced techniques such as extreme ultraviolet (EUV) lithography, which pushes feature sizes even further into the nanometer regime. Collectively, these advantages have established UV lithography as the dominant patterning technology in modern semiconductor fabrication Intel.

Challenges and Limitations in UV Lithography

Despite its central role in semiconductor manufacturing, ultraviolet (UV) lithography faces several significant challenges and limitations as device dimensions continue to shrink. One of the primary issues is the diffraction limit imposed by the wavelength of UV light, which restricts the minimum feature size that can be reliably patterned. As manufacturers push for sub-10 nm nodes, even deep ultraviolet (DUV) lithography at 193 nm struggles to achieve the necessary resolution without resorting to complex techniques such as multiple patterning, which increases process complexity, cost, and the risk of defects ASML.

Another challenge is the photoresist material’s sensitivity and performance. As feature sizes decrease, photoresists must offer higher resolution, better line edge roughness, and improved etch resistance. However, these improvements often come at the expense of sensitivity, requiring higher exposure doses and reducing throughput IMEC. Additionally, the use of high-intensity UV sources can accelerate the degradation of optical components, leading to increased maintenance and operational costs.

Overlay accuracy and process control also become more difficult as device geometries shrink. Achieving precise alignment between successive layers is critical, and any misalignment can result in device failure. Furthermore, the escalating complexity of mask fabrication for advanced nodes increases both the cost and the potential for defects, making mask inspection and repair more challenging SEMI.

These limitations have driven the industry to explore alternative lithography techniques, such as extreme ultraviolet (EUV) lithography, to overcome the inherent constraints of traditional UV lithography.

Impact on Semiconductor Device Scaling and Performance

Ultraviolet (UV) lithography has played a pivotal role in advancing semiconductor device scaling and enhancing performance. As the industry has pursued Moore’s Law, the ability to pattern ever-smaller features on silicon wafers has been essential. UV lithography, particularly deep ultraviolet (DUV) and extreme ultraviolet (EUV) variants, has enabled the reduction of critical dimensions, allowing for the integration of more transistors per chip and the realization of higher computational power and energy efficiency. The transition from traditional mercury lamp-based UV sources to excimer lasers (193 nm ArF for DUV and 13.5 nm for EUV) has been instrumental in achieving sub-10 nm node manufacturing, directly impacting device miniaturization and performance improvements ASML Holding.

The impact of UV lithography on device scaling is evident in the shrinking of gate lengths and interconnect pitches, which reduces parasitic capacitance and resistance, thereby improving switching speeds and lowering power consumption. However, as feature sizes approach the physical limits of light-based patterning, challenges such as line edge roughness, stochastic defects, and overlay accuracy become more pronounced. Advanced techniques like multiple patterning and the adoption of EUV lithography have been developed to address these issues, enabling continued scaling while maintaining yield and reliability Taiwan Semiconductor Manufacturing Company (TSMC).

Overall, UV lithography remains a cornerstone technology in semiconductor manufacturing, directly influencing the pace of innovation in microelectronics by enabling smaller, faster, and more energy-efficient devices Intel Corporation.

Major Industry Players and Recent Innovations

The landscape of ultraviolet (UV) lithography in semiconductor manufacturing is shaped by a handful of major industry players, each driving innovation to meet the demands of ever-shrinking device geometries. ASML Holding N.V. stands as the global leader in lithography systems, particularly with its advancements in deep ultraviolet (DUV) and extreme ultraviolet (EUV) technologies. ASML’s EUV scanners, such as the Twinscan NXE series, have enabled the production of chips at the 5 nm and 3 nm nodes, pushing the boundaries of Moore’s Law. Canon Inc. and Nikon Corporation are also significant contributors, offering DUV lithography equipment that remains essential for many critical and non-critical layers in semiconductor fabrication.

Recent innovations focus on increasing throughput, improving resolution, and reducing the cost of ownership. ASML’s High-NA EUV systems, for example, promise sub-2 nm patterning capabilities, leveraging higher numerical aperture optics to achieve finer feature sizes. Meanwhile, Canon and Nikon have introduced multi-patterning and advanced overlay control technologies to extend the utility of DUV lithography. Additionally, collaborations between equipment manufacturers and semiconductor foundries, such as Taiwan Semiconductor Manufacturing Company (TSMC) and Samsung Electronics, have accelerated the adoption of next-generation lithography tools and process integration.

These advancements are critical as the industry faces challenges related to pattern fidelity, defect control, and cost efficiency. The ongoing R&D investments and strategic partnerships among these major players continue to shape the future trajectory of UV lithography in semiconductor manufacturing.

Future Trends: What’s Next for UV Lithography?

The future of ultraviolet (UV) lithography in semiconductor manufacturing is shaped by the relentless drive toward smaller, more powerful, and energy-efficient devices. As traditional deep ultraviolet (DUV) lithography approaches its physical and economic limits, the industry is increasingly focused on extreme ultraviolet (EUV) lithography, which operates at a wavelength of 13.5 nm. EUV enables the patterning of features below 7 nm, a critical threshold for next-generation logic and memory chips. However, EUV adoption faces significant challenges, including the need for high-power light sources, advanced photoresists, and defect-free mask technology. Leading manufacturers such as ASML Holding are investing heavily in overcoming these hurdles, with recent advances in source power and throughput making high-volume EUV manufacturing increasingly viable.

Beyond EUV, research is exploring even shorter wavelengths, such as soft X-ray lithography, though these technologies remain in the experimental stage due to extreme technical complexity and cost. Meanwhile, complementary approaches like multiple patterning and directed self-assembly are being developed to extend the capabilities of existing UV lithography tools. The integration of machine learning and advanced computational lithography is also expected to optimize process control and defect detection, further enhancing yield and efficiency. As the semiconductor roadmap pushes toward the angstrom era, the evolution of UV lithography will be defined by a combination of incremental improvements and disruptive innovations, ensuring its continued relevance in the face of ever-tightening design rules and performance demands (SEMI).

Conclusion: The Lasting Impact of UV Lithography on Semiconductor Manufacturing

Ultraviolet (UV) lithography has left an indelible mark on the evolution of semiconductor manufacturing, serving as a cornerstone technology that has enabled the relentless miniaturization and performance improvements of integrated circuits. By harnessing shorter wavelengths of light, UV lithography has facilitated the patterning of ever-smaller features on silicon wafers, directly contributing to the realization of Moore’s Law and the exponential growth in computational power over the past several decades. The transition from traditional mercury lamp-based systems to deep ultraviolet (DUV) and, more recently, extreme ultraviolet (EUV) lithography has pushed the boundaries of resolution and process control, allowing for the production of chips with feature sizes well below 10 nanometers ASML Holding NV.

The impact of UV lithography extends beyond technical achievements; it has fundamentally shaped the economics and innovation cycles of the semiconductor industry. The ability to produce smaller, faster, and more energy-efficient devices has fueled advancements in computing, telecommunications, and consumer electronics, underpinning the digital transformation of society. Moreover, the ongoing refinement of UV lithography techniques—such as multiple patterning and advanced photoresists—continues to drive cost-effective scaling, even as physical and material limits are approached Semiconductor Industry Association.

In summary, UV lithography remains a pivotal enabler of semiconductor progress. Its legacy is evident in the ubiquity of high-performance electronics and the ongoing pursuit of technological innovation, ensuring its relevance in both current and future generations of chip manufacturing.